Structural steel detailing is an important task that takes place at multiple stages of the building process. Detailers will produce intricate drawings that inform steel fabricators of exactly what materials they need to produce along with their measurements. They will then create drawings to support the erection of the project and explain how the steel parts should be assembled.

BIM or, “building information modeling” is a type of application that enables steel detailers to produce these drawings in a highly specific, comprehensive way. These 3D, multi-faceted modeling applications incorporate precise visual drawings, as well as written technical information.

At Spartan Scanning Solutions, we combine the latest innovations in modeling and scanning technology to help facilitate successful building projects. The following is a list of ways in which we have seen BIM technology improve the structural steel detailing process.

Budget accuracy

One of the main responsibilities of structural steel detailers is to create visual representations that are accurate enough to be used throughout the budgeting process. Stakeholders should be able to rely on the outlined quantity of metal necessary to bring their vision to life, and avoid any missteps due to poorly laid-out drawings. BIM enables structural steel detailers to produce highly specific representations and well-calculated measurements backed by functions built into these advanced platforms. This results in less room for error, giving fabricators and builders the information they need to stay within the projected budget.

Viewing each stage of building process

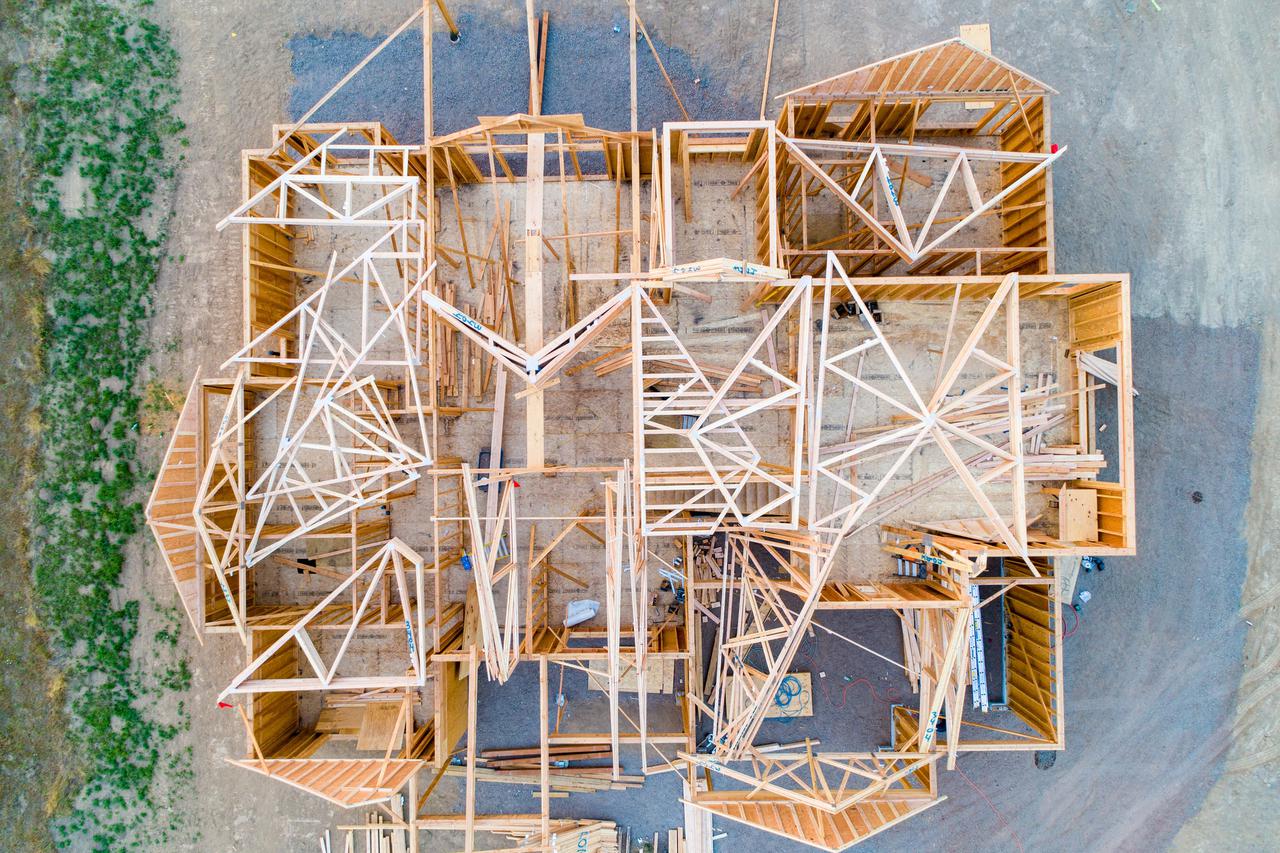

Without BIM technology, structural steel detailing usually requires multiple drawings to represent each stage of the building process. This can make it difficult for stakeholders to visualize the final result and make informed decisions throughout the building process. With BIM however, structural steel detailing can be done all in a single application by overlaying 3D images of each building phase. This makes it far easier for all parties to understand what materials are necessary to complete the project, how much time needs to be allocated, what the total cost will be, and other useful information.

Communication between stakeholders

Another benefit of building information modeling for structural steel detailers is that it is versatile enough to incorporate other applications and communication platforms. This is useful for building projects where there are many different stakeholders who may want to add their input to the initial drawings. Where some digital modeling applications prevent integration for the purpose of capitalizing on their own product, BIM allows users to share information between project managers, designers, manufacturers, and more. This makes it possible to consolidate all important information into one highly organized application. Such technology leaves less room for error and makes it easier for all parties to contribute to the detailing process.

Bring projects to fruition faster

Building projects often run much longer than initially intended – especially when team members do not have reliable tools to complete each step of the fabrication and erection process. Prior to the introduction of BIM, structural steel detailing was far more susceptible to false measurements and other technical errors. Mistakes are often not detected until drawings are passed onto those responsible for the next stage of the building process. This can mean starting over after already investing time, energy, and money into the project. With the right application, structural steel detailing can be done faster and with greater accuracy, making it much easier to stay on schedule.

Do you have an upcoming building project that requires structural steel detailing? At Spartan Scanning Solutions, we offer industry-leading technology that helps expedite every stage of the building process and guarantees incredible results. Contact us today for more information on our top-rated solutions.