The rise of 3D laser scanning technology has transformed a wide range of industries, offering precise, efficient, and versatile solutions. When paired with green technology, 3D laser scanners become even more impressive, providing an eco-friendly approach that boosts productivity while cutting down on environmental impact. In this blog, we’ll dive into the industrial uses of 3D laser scanner services combined with green technology that exemplifies the use case for a digital twin.

What is 3D Laser Scanning?

3D laser scanning is a non-contact, non-destructive technology that captures the shape of physical objects using laser light. This technology creates “point clouds” of data from the surface of an object, which can then be turned into detailed 3D models or “digital twins.”

Integration with Green Technology

Green technology, also known as environmental technology, focuses on mitigating or reversing the effects of human activity on the environment. When you integrate 3D laser scanning with green technology, you get a powerful digital twin of your facility that supports sustainable practices. This combo helps reduce waste, conserve energy, and minimize the carbon footprint across various industrial applications.

Industrial Applications of 3D Laser Scanning with Green Technology

1. Construction and Architecture

Sustainable Building Design

3D laser scanning allows architects and engineers to create highly accurate models, or digital twins, of existing structures and sites. These digital twins reduce material waste and rework, leading to more efficient use of resources. When you add green technology into the mix, the materials used are sustainable, enhancing the environmental benefits.

Energy Efficiency Assessments

3D laser scanners can evaluate the energy efficiency of buildings by pinpointing areas of heat loss and poor insulation. This data helps in designing energy-efficient solutions that lower a building’s carbon footprint.

2. Manufacturing and Production

Optimized Production Processes

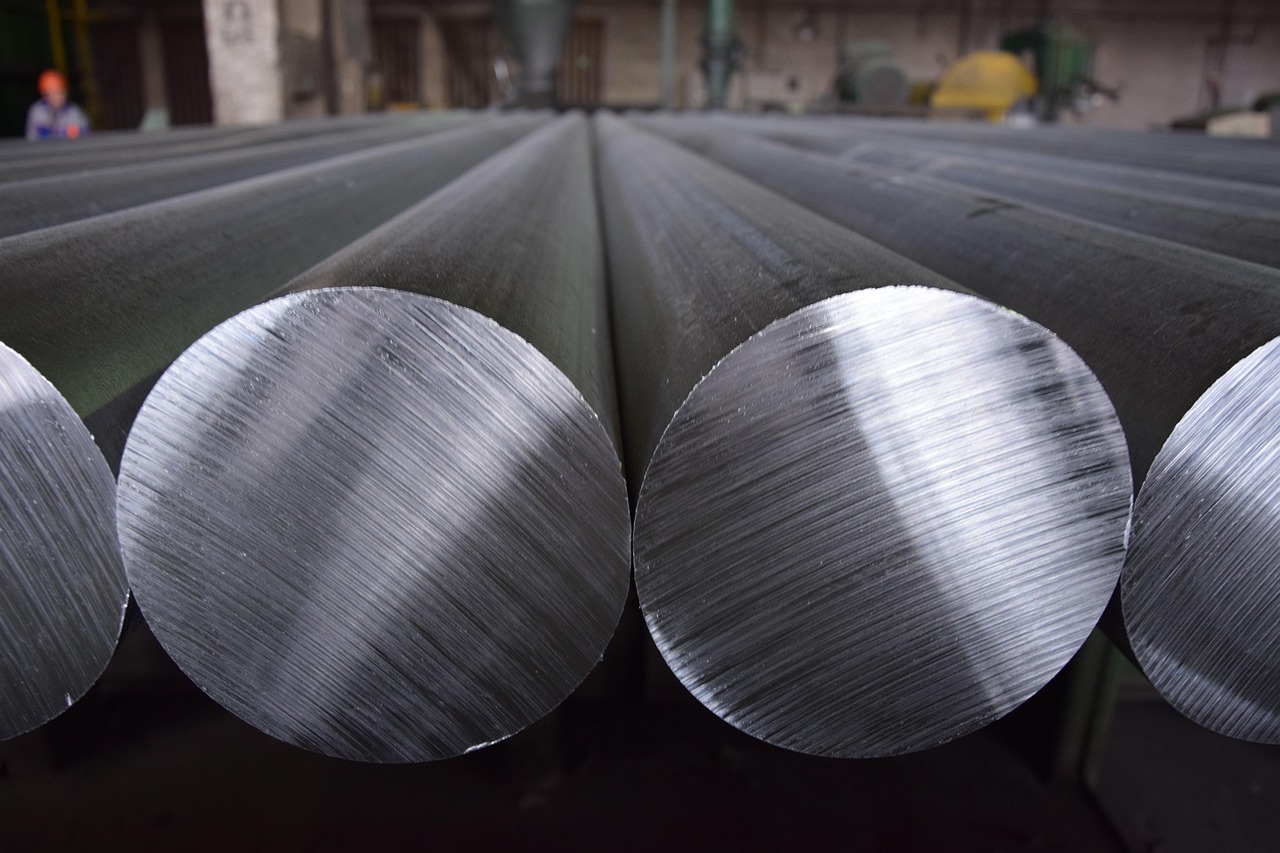

In manufacturing, 3D laser scanners ensure high-quality production with minimal waste by providing precise measurements of components. The digital twins created from these scans allow for detailed analysis and optimization. Integrating green technology means using eco-friendly materials and processes, leading to sustainable manufacturing practices.

Reverse Engineering

3D laser scanning makes reverse engineering a breeze, allowing manufacturers to accurately recreate parts and components. This supports recycling older products and reducing waste, aligning perfectly with green technology principles.

3. Heritage Conservation

Preservation of Historical Sites

3D laser scanning is invaluable for preserving historical and cultural heritage sites. It enables detailed documentation and analysis without physical interference, ensuring these sites are preserved for future generations. The digital twins created from these scans provide comprehensive records. Using green technology ensures that the preservation methods are sustainable and environmentally friendly.

Virtual Tours and Education

Creating virtual models, or digital twins, of historical sites allows for virtual tours, cutting down on the need for physical travel and its associated environmental impact. These models are also great for educational purposes, promoting awareness and appreciation of heritage while sticking to green principles.

4. Environmental Monitoring and Management

Topographic and Environmental Surveys

3D laser scanners are used in environmental monitoring to conduct precise topographic surveys. These surveys help in tasks like erosion monitoring, forest management, and natural disaster assessment. The digital twins produced from these surveys provide a detailed, accurate representation of the environment. Green technology ensures these practices are sustainable.

Renewable Energy Projects

3D laser scanning supports the development of renewable energy projects, such as wind farms and solar panel installations. Accurate site assessments and digital twins ensure optimal placement and efficiency of these renewable energy sources, pushing us towards more sustainable energy.

5. Recycling

Waste Reduction and Material Reuse

3D laser scanning is a game-changer in the recycling industry by accurately assessing the condition and composition of materials that can be reused. The creation of digital twins helps in sorting and processing recyclable materials efficiently, reducing waste and promoting a circular economy.

Enhanced Recycling Processes

By creating detailed models, or digital twins, of recycling facilities and processes, 3D laser scanning can pinpoint inefficiencies and areas for improvement. Integrating green technology ensures these enhancements lead to more sustainable recycling practices, minimizing energy consumption and environmental impact.

Product Lifecycle Management

3D laser scanning helps track the lifecycle of products, from manufacturing to disposal. Understanding the complete lifecycle allows industries to design products with recycling in mind, ensuring materials can be easily reclaimed and reused, further supporting green technology initiatives.

6. Pre-Production, During Manufacturing, and Failure Investigations

Pre-Production Planning

Before production begins, 3D laser scanning can create accurate digital twins of prototypes and designs. This allows for thorough testing and adjustments, ensuring that the production process is optimized for efficiency and minimal waste. Green technology integration ensures that the planning phase considers environmental impacts, selecting sustainable materials and processes from the start.

During Manufacturing

During the manufacturing process, 3D laser scanning can continuously monitor and inspect components. The digital twins created provide real-time data that helps in maintaining quality control and identifying any deviations from the design. This real-time monitoring reduces the likelihood of defective products, leading to less waste and a more efficient use of resources.

Failure Investigations

In the event of a failure, 3D laser scanning can be used to analyze and diagnose the issue quickly. Creating a digital twin of the failed component allows engineers to conduct a detailed examination without further damaging the part. This helps in identifying the root cause and developing solutions that prevent future failures, ultimately supporting more sustainable and reliable manufacturing practices.

Conclusion

Bringing together 3D laser scanner services with green technology offers a powerful tool for various industries aiming to enhance efficiency and precision while cutting down on environmental impact. From construction and manufacturing to heritage conservation, environmental management, recycling, and pre-production planning, the combined benefits of these technologies pave the way for a more sustainable future. Embracing these advancements not only drives innovation but also aligns industrial practices with the urgent need for environmental stewardship.

Partner with Spartan Scanning Solutions for drone and 3D laser scanner services in the Midwest.

At Spartan Scanning Solutions, we identified a gap in the engineering field and set out to fill it using cutting-edge technology. Our advanced 3D laser scanning and drone services transform how clients manage their projects, delivering exceptional data quality and accuracy. By integrating green technology, we ensure that every project is not only efficient but also sustainable, customized to meet your specific needs and goals.

From initial surveys to risk mitigation, our expertise and top-tier equipment offer comprehensive solutions that redefine possibilities in design and construction.