The Evolution of Reality Capture Technology

Reality capture technology is truly changing the game. Here at Spartan Scanning Solutions, we’re not just watching this transformation unfold; we’re actively driving it forward. We’ve quickly established ourselves as pioneers in providing cutting-edge reality capture and digital twin solutions tailored specifically for the manufacturing sector. As we explore the evolution of reality capture technology and our role in this journey, we’ll highlight how our innovative approach is reshaping the future of manufacturing, enhancing efficiency, safety, and sustainability for our clients.

Our Evolution Alongside Reality Capture Technology

We’ve witnessed and actively participated in the remarkable evolution of reality capture technology. From its early days of basic 3D scanning in architecture and construction, we’ve been at the forefront of adapting and enhancing these technologies for the manufacturing sector. Our team has embraced each technological leap:

- The advancement of laser scanning technology

- The integration of photogrammetry for comprehensive data capture

- The game-changing introduction of LiDAR and SLAM technologies

Most recently, we’ve been leading the charge in the development and implementation of digital twins – virtual replicas that are transforming how our clients monitor, analyze, and optimize their manufacturing processes.

Spartan’s Unique Approach

At Spartan, we’re not just using the latest tools; we’re actively shaping how these technologies solve real-world manufacturing challenges. Our approach is threefold:

- Pioneering Digital Solutions: We’re transitioning reality capture from theory to practice, helping our clients implement advanced technologies to improve their operations.

- Enhancing Maintenance and Repair: Our digital scan technology enables easy onsite scanning, offsite diagnosis, and significantly reduced facility downtime. We’re shifting the industry from reactive to predictive maintenance models.

- Creating Digital Twins: We’re pushing the boundaries by implementing digital twin technologies that allow for real-time monitoring, predictive maintenance, and enhanced operational control.

Our Comprehensive Service Suite

We offer a wide range of services tailored to the unique needs of industrial manufacturers:

What sets us apart is our holistic approach. We don’t just offer individual services; we provide end-to-end solutions from initial scanning to the implementation and maintenance of digital twins.

The Spartan Difference

We specialize in industrial manufacturing, allowing us to develop deep expertise in this sector’s unique challenges. Our commitment to sustainability is reflected in our integration of green technology into our services. We pride ourselves on our customized solutions. We know that each of our clients has unique needs, and we work closely with them, educating them about the technology and acting as true partners in their digital transformation journey. Our team is constantly integrating the latest advancements in reality capture and digital twin technology. We’re not content with off-the-shelf solutions; we ensure our clients always have access to the most advanced tools available.

The Impact We’re Making

We’ve seen firsthand the significant impact our approach has on industrial manufacturing:

- Improved efficiency through accurate digital representations

- Reduced downtime through predictive maintenance

- Substantial energy savings

- More sustainable manufacturing practices

We’ve worked with various industrial manufacturers, consistently delivering significant reductions in maintenance costs, improved operational efficiency, enhanced safety measures, and substantial energy savings.

Looking to the Future

As we continue to innovate, we’re excited about the future of reality capture in manufacturing. We’re actively working on:

- Integrating AI and machine learning with our reality capture technology

- Enhancing our focus on sustainability

- Increasing integration with IoT for more comprehensive digital twins

What challenges do we help our clients overcome?

Sustainable Approach: The company stands out by incorporating green technology into their services, ensuring a more sustainable approach to manufacturing practices

Energy Efficiency: Spartan’s technology allows for detailed analysis of energy usage, leading to substantial energy savings for manufacturers

Waste Reduction: The integration of green technology and optimization of processes lead to more sustainable manufacturing practices, reducing waste and environmental impact

Digital Solutions: By providing digital twins and reality capture services, Spartan reduces the need for physical prototypes and on-site visits, which can lead to reduced material waste and lower carbon emissions from travel

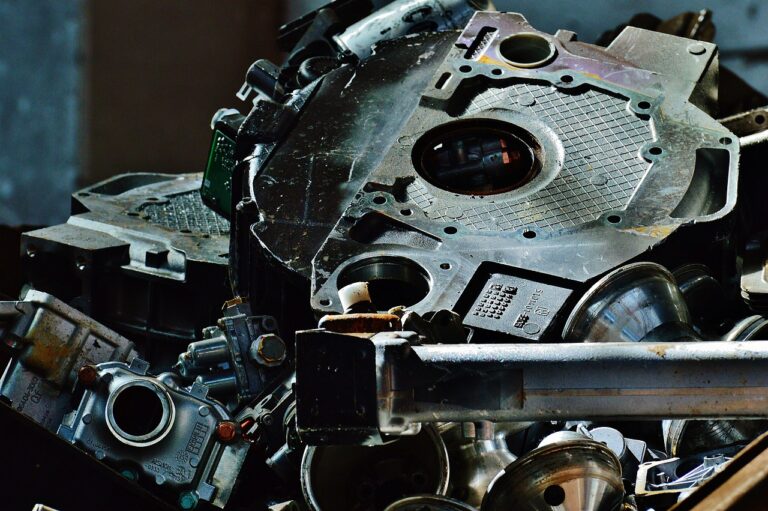

Predictive Maintenance: Their digital twin technology enables predictive maintenance, which can extend the life of equipment and reduce the need for premature replacements, thus conserving resources

Process Optimization: By providing accurate digital representations of manufacturing facilities and processes, Spartan enables manufacturers to identify and eliminate inefficiencies more effectively, which often results in reduced energy consumption and waste

Sustainability Improvements: The company’s solutions are designed to help clients achieve their sustainability objectives through the strategic use of data and visualization technologies

How we have turned reality capture technology into a competitive advantage for us and our clients.

Our competitive advantage stems from our ability to stay ahead of the curve. While many companies are still grappling with basic 3D scanning, we’ve moved far beyond that. We’ve integrated cutting-edge technologies like LiDAR, SLAM, and advanced photogrammetry into our solutions. This allows us to offer services that are not just more accurate and comprehensive, but also faster and more cost-effective than traditional methods. Let’s break down our key services and how they leverage the latest in reality capture technology:

Reality Capture Services:

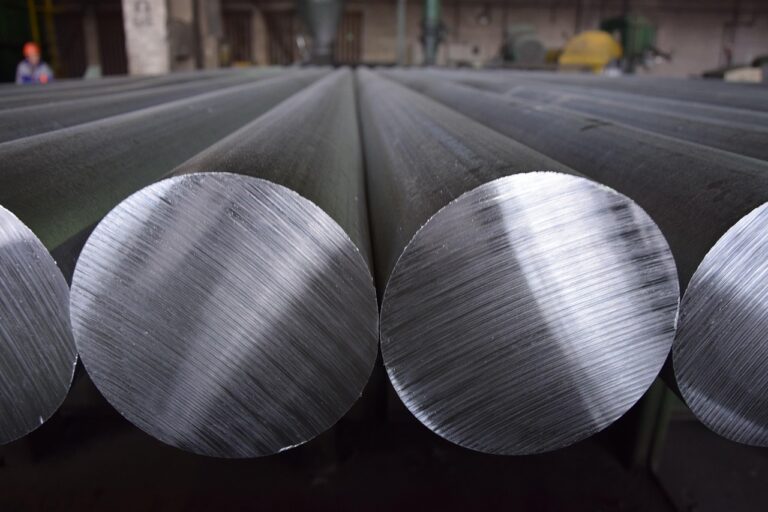

We use state-of-the-art laser scanners, high-resolution cameras, and drones to create incredibly detailed 3D models of manufacturing facilities and equipment. These aren’t just static models – they’re dynamic, data-rich representations that can be updated in real-time. This level of detail and flexibility was simply not possible with earlier reality capture technologies.

UAV Operations:

Our use of unmanned aerial vehicles (UAVs) for aerial surveys and inspections is a game-changer. It allows us to capture data from vantage points that were previously inaccessible or dangerous to reach. This is particularly valuable for large-scale manufacturing operations or facilities with complex external structures.

Construction Verification:

The precision of our reality capture technology allows us to offer construction verification services that are unmatched in accuracy. We can compare as-built conditions to design specifications with millimeter-level precision, helping our clients catch and correct discrepancies early in the construction process.

MEP Solutions:

The complexity of Mechanical, Electrical, and Plumbing systems in modern manufacturing facilities demands advanced mapping solutions. Our reality capture technology allows us to create detailed, interactive 3D models of these systems, making maintenance and upgrades far more efficient and less disruptive.

As-Built Modeling:

Our as-built models are more than just 3D representations – they’re information-rich databases that can be integrated with other systems for comprehensive facility management. This level of integration and data richness is a direct result of advancements in reality capture technology.

Digital Twin Creation and Implementation:

This is perhaps where our competitive advantage shines brightest. By leveraging the latest in reality capture, IoT, and data analytics, we create digital twins that are true real-time replicas of our clients’ physical assets and processes. These digital twins enable predictive maintenance, process optimization, and data-driven decision making at a level that was unimaginable just a few years ago.

What sets us apart is not just our use of advanced technology, but how we apply it to solve real-world manufacturing challenges. We’ve developed deep expertise in the industrial manufacturing sector, allowing us to tailor our solutions to the unique needs of each client.

Moreover, our commitment to sustainability gives us an edge in an increasingly eco-conscious market. We’ve integrated green technology into our services, helping our clients reduce their environmental impact while improving operational efficiency. Our holistic, end-to-end approach is another key differentiator. We don’t just provide the technology – we partner with our clients throughout their digital transformation journey. From initial scanning to ongoing maintenance and optimization of their digital twins.

As reality capture technology continues to evolve, so do we. We’re already exploring the integration of AI and machine learning to make our digital twins even more intelligent and autonomous. We’re also looking at ways to expand the use of augmented reality, allowing workers to interact with digital data in the physical world more intuitively.

Conclusion

The evolution of reality capture technology in industrial manufacturing, it’s clear that Spartan Scanning Solutions is not just a participant in this transformation but driving it forward. Since our inception, we have embraced cutting-edge advancements, from laser scanning to digital twins, allowing us to offer innovative solutions that enhance efficiency, safety, and sustainability for our clients.

Our commitment to providing tailored services—whether through reality capture, UAV operations, or digital twin implementation—sets us apart in a competitive landscape. By focusing on the unique needs of the manufacturing sector and integrating green technology into our offerings, we help our clients optimize their operations while reducing their environmental impact.

Looking ahead, we are excited about the future of reality capture technology and the opportunities it presents. With ongoing advancements in AI, machine learning, and augmented reality, we are poised to continue leading the charge in transforming how manufacturers operate. We don’t just offer services; we provide a pathway to a more efficient, safe, and sustainable future in industrial manufacturing. We invite you to join us on this journey as we shape the future together.